Why Standard Batteries Fail Below Freezing

Understanding the science behind battery failure in cold temperatures and how wide temp batteries overcome these challenges through advanced chemistry and intelligent design.

Key Takeaway

Standard batteries lose up to 50% of their capacity at 32°F (0°C) and become completely unusable below 0°F (-18°C) due to fundamental chemical and physical limitations that wide temp batteries are specifically engineered to overcome.

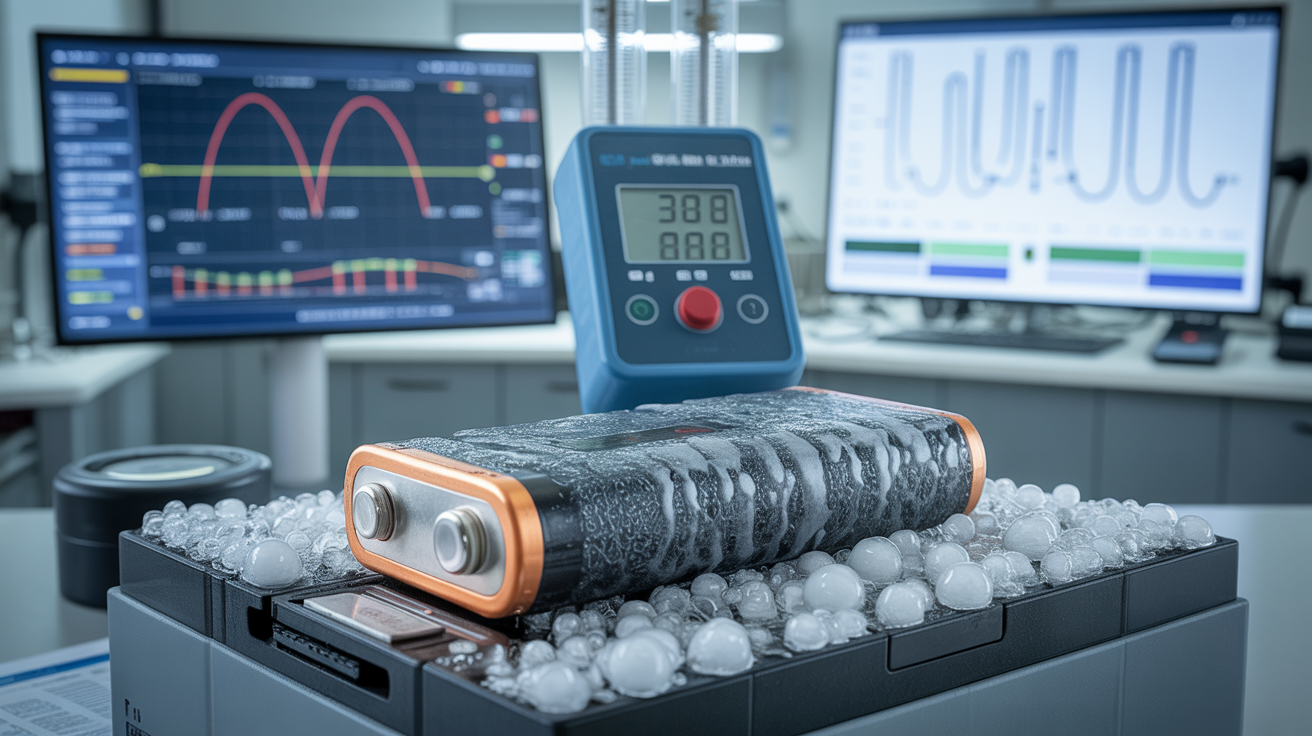

The Physics of Battery Failure in Cold

When temperatures drop below freezing, conventional batteries face multiple simultaneous challenges that compound to create complete system failure. Understanding these mechanisms is crucial for anyone operating critical systems in cold environments.

1. Electrolyte Viscosity and Ion Mobility

The primary cause of cold weather battery failure is the dramatic increase in electrolyte viscosity. As temperature decreases:

- Ion mobility decreases exponentially - The ions that carry electrical charge become sluggish, reducing current flow

- Internal resistance skyrockets - What was 50mΩ at room temperature can become 500mΩ or higher at -20°F (-29°C)

- Voltage drops under load - Equipment may shut down even though the battery shows charge when unloaded

Temperature Impact on Battery Performance

- • 50% capacity loss

- • 300% increase in internal resistance

- • Risk of electrolyte freezing

- • 70% capacity loss

- • Cannot charge safely

- • Permanent damage risk

2. Lithium Plating and Permanent Damage

Perhaps more critical than temporary performance loss is the permanent damage that occurs when standard lithium batteries are charged in cold conditions:

- Lithium metal deposition - Instead of intercalating into the anode, lithium forms metallic dendrites

- Dendrite growth - These sharp metallic structures can pierce the separator, causing internal shorts

- Capacity fade - Each cold charging cycle permanently reduces battery capacity

- Safety hazards - Dendrites create fire and explosion risks

How Wide Temp Batteries Overcome These Challenges

Advanced Electrolyte Formulations

Intelligent Power's wide temp batteries use proprietary electrolyte formulations that maintain fluidity and conductivity at sub-zero temperatures:

Standard Battery Issues

- • Electrolyte freezes at 5°F (-15°C)

- • Ion mobility drops 90% at 0°F

- • Charging prohibited below 32°F

- • Permanent damage from cold charging

Wide Temp Solutions

- • Specialized electrolytes remain fluid to -40°F

- • Ion mobility maintained through polymer additives

- • Safe charging down to -20°F (-29°C)

- • No dendrite formation or permanent damage

Intelligent Battery Management Systems

Advanced BMS technology plays a crucial role in cold weather operation:

- Temperature monitoring - Precise thermal sensors throughout the battery pack

- Adaptive charging algorithms - Automatically adjusts charging parameters based on temperature

- Thermal management - Integrated heating elements for wide temp cold applications

- Predictive algorithms - AI-driven systems that optimize performance before problems occur

Real-World Applications and Case Studies

Arctic Communications

A recent deployment of Intelligent Power batteries in Arctic communications equipment demonstrated the dramatic difference in performance:

"While standard batteries completely failed at -30°F, the Intelligent Power wide temp batteries maintained full operational capacity, ensuring critical communications remained online during the entire 72-hour mission."

Oil & Gas Remote Monitoring

In North Dakota oil fields, where temperatures regularly drop below -20°F (-29°C), standard battery systems required monthly replacement. Wide Temp temperature batteries have operated continuously for over 18 months without maintenance.

The Bottom Line for Critical Applications

For applications where failure is not an option—emergency services, critical infrastructure, industrial operations—understanding why standard batteries fail in cold weather is just the beginning. The solution lies in purpose-built wide temp battery technology that addresses these challenges at the fundamental chemistry level.

Engineering Recommendation

Any application expecting temperatures below 40°F (4°C) should specify wide temp batteries from the design phase. Retrofitting after cold weather failures is significantly more expensive than choosing the right technology initially.

Leading expert in wide temp battery technology with over 20 years of experience in advanced lithium battery development. Darrell has personally overseen the testing and deployment of battery systems in environments ranging from -50°F Arctic conditions to 140°F desert operations.